- Home

- Training Courses ▼

- Advanced Motor Design

- Application of Industrial Motors, Drives and Transformers

- Electric Motor Technology for Non-Engineers

- Induction Motor Design

- Motor Manufacturing Methods

- Permanent Magnet AC Motor Design--BLDC/IPM/SMPM

- Reluctance Motor Design- Switched & Synchronous Reluctance

- Single Phase Induction Motor Design

- Thermal Design of Motors

- Winding 3-Phase Motors--Hands-On Part1

- Enroll Now

- Design of Electric Machines ▼

- Prototyping and Testing ▼

- Store

- Calendar of Events

- Careers/Additional Resources

- Contact

About Us

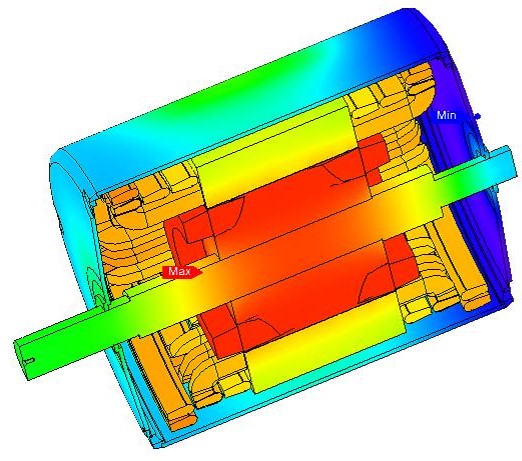

Thermal Design of Motors - Taking Theory to Practice

Next Offering:

All courses ON HOLD until further notice

***Now Produced ON-LINE****

Dates:

TBD

Location:

LIVE, ONLINE Classroom

View previous Thermal Brochure Here

Email us at

Training@AdvancedMotorTech.com

You will learn about practical Thermal Design Methods and the latest trends, including:

** Understanding Heat Sources and Sinks, Heat transfer, Temperature, Building your own Model

** When to choose Natural Convection versus Forced Convection Cooling versus Liquid Cooling

** New Analysis Techniques, Computer-Aided Engineering (CAE), Quick Approximations

** Thermal Design Trade-offs affecting Efficiency, Power Density, Thermal Target, Cost, Reliability

** Design using New Materials, New Manufacturing Methods, New CAE Tools

This is the FIRST course of its kind anywhere in the world! Learn the **How-to** for application-oriented

thermal design for all types of motors & generators. Learn electric machine thermal design techniques

based on academic theory and years of practical experience, taking manufacturing and costs into account.

The material in this course is engineering you cannot find in a book, & you cannot get from software training! Presentations include

specification requirements, design steps, balancing cost and thermal performance, good rules of thumb, analysis approaches & test

methods. The course material applies to motors and generators used in industry, hybrid electric drives, traction and propulsion

systems, wind turbines, home appliances, aerospace applications. The material applies to radial flux, axial flux and linear machines.

This NEW COURSE is a combination of the latest thermal design concepts & computer techniques, with a heavy dose of experience.

You will learn the major similarities & differences of cooling systems, fabrication methods, choices of materials, and analysis tools.

The MotorCAD software will be used for illustration purposes to help understanding, but this is NOT a software course.

The primary goal of this course is to provide an up-to-date, practical foundation of thermal design considerations and analysis techniques to produce

accurate and realistic results based on the electrical, magnetic, mechanical, material and manufacturing process interactions.

- Fundamentals of Thermal Design

- Heat Sources, Effect of Temperature

- Material Considerations for Thermal Design

- Thermal Estimation, Analysis and Modeling

- Thermal Considerations in Motor and Generator Design

- Practical Thermal Design in Motor and Generator

- Testing for Thermal Performance and Parameters

Advanced MotorTech, LLC 6822 22nd Avenue North -- Suite #265, St. Petersburg, FL 33710 USA

Phone: 727- 412-8200 Sales@AdvancedMotorTech.com

Copyright © 2021 Advanced MotorTech LLC. All rights reserved